A new material, construction, and system–BioMarble by Hannah Elisabeth Jones

by Purva Chawla

The crackle and crunch of paper, the stretch, and bend of a textile.

Rather uniquely, Hannah Elisabeth Jones’s material BioMarble* possesses both.

Part 1: The Physical and Sensorial

Several physical and compositional qualities give BioMarble a real personality, making it memorable and distinct within the ocean of surface innovation seen in our industries today.

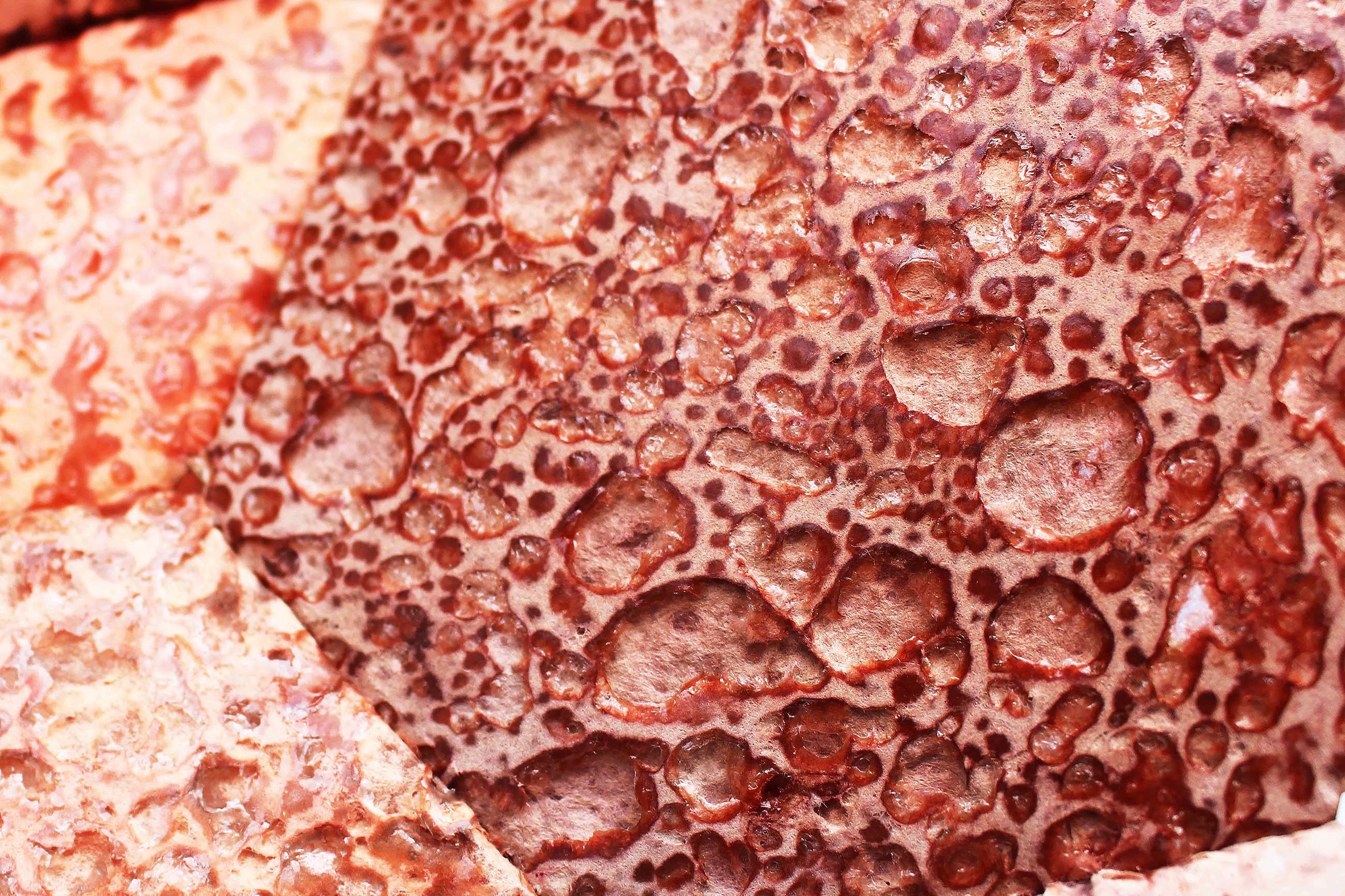

Its pitted, textured surface is key to a strong visual and tactile appeal, and so is the ombré effect and subtle palette of colors seen in every BioMarble composition.

A close up of Hannah Elisabeth Jones' 'Burnt Umber' BioMarble, 2017

A sense of structure balances BioMarble's natural flexibility and stretch–a duality which means that the material can both softly drape over a surface, as well as hold its own in more three-dimensional rigid forms. This ability to possess textile-like flow, AND create tangible volume as a stiffer material does, is a rare combination.

*BioMarble is a patent pending material developed by Hannah Elisabeth Jones.

Part 2: The Systemic

At this point, it is crucial to discuss what gives BioMarble these dual, almost contradictory qualities. The roots of these abilities lie in its structure–composed of hexagonal, individually cast and colored pieces, BioMarble is a modular assembly.

Hannah Elisabeth Jones, BioMarble Installation 'Growth', 2017

The use of traditional quilting techniques by Hannah to patch together individual units is what lends the material its inherent flexibility and strength. Her method is inspired by traditional patchwork quilts which typically involve uniting and recycling scrap fabric. This ethos ties in well with Hannah’s interpretation, where waste paper becomes her raw material.

The fact that BioMarble is a tested, modular system, rather than solitary chunks of a new material, makes it even more valuable, and applicable to a variety of current and future uses.

Part 3: The Sustainable

BioMarble is a biodegradable material–one whose chief ingredient is discarded, waste paper. The material and its recipe were sparked by Hannah's concern for the environment, and the awareness that an immense amount of paper was being wasted around her, during her time studying Textiles in Practice at the Manchester School of Art.

Waste paper is the chief ingredient of Hannah Elisabeth Jones's BioMarble material

A great deal of material testing ensued after identifying her raw material, and abundant hit and trial lead Hannah to the composition of healthy materials, and surface effects we see today. Begun in her final year, BioMarble became Hannah’s graduation project and has since been widely recognized across the UK and Europe. The development of the material was supported greatly by the Manchester School of Art, and through large-scale commissions, by companies and galleries in Manchester.

BioMarble color and material testing, Hannah Elisabeth Jones

Since waste paper is an abundant resource today, Hannah’s material invention can be scaled-up immensely. Through its sourcing and applications, it can also be designed to engage with entire communities and perform a robust systemic role.

For viewers and users, the material seeks to promote sustainable thinking and new ideas of material consumption, waste, and reuse.

Part 4: The Designer and her Future

2017 was a great year for Hannah Jones, BioMarble's young designer, and recent graduate of the unique 'Textiles in Practice' program at Manchester School of Art.

BioMarble was seen at prominent design events such as New Designers, MoOD Brussels, London Design Fair, Design Junction, Surface & Materials Show NEC, and the Northern Design Festival. During the year Hannah also created large-scale commissioned works for Bruntwood and the Vertical Gallery for Manchester School of Art. While Bruntwood commissioned her to create an artwork for their offices in Manchester, in recognition of her ingenuity, they have also since funded the copyright protection of her work through Anti-Copying in Design (ACID) membership. BioMarble is currently a patent pending material.

Hannah Elisabeth Jones' 'Clwydian Range', BioMarble at the Surface and Materials Show, 2017

Up ahead in 2018, Hannah and her work will be seen at the Surface Design Show next week, as part of MIX Magazine’s exhibit focussed on the future of materials and sustainability. A talk and workshop at the Material ConneXion Materials Library at Ravensbourne University will follow in March. Hannah is also collaborating with 2LG Studio to exhibit her 'Growth' design in their sustainable garden office pod for the Ideal Home Show (17th March – 2nd April).

For those following MaterialDriven’s built projects and curated exhibitions, Hannah’s work will be a part of our exhibit for Future Thinkers at The BALTIC Centre for Contemporary Art in Newcastle this summer. Samples of her Burnt Umber material are also a permanent member of Materials in Motion–our traveling Materials Library (last hosted by Somerset House in London).

Last week we caught up with Hannah, digging deeper into her process, her vision for the future of BioMarble and the formats she sees it taking.

MD: Hannah, while creating BioMarble, are there challenges you face with your material ingredients and making process?

Hannah: Initially, I did not feel like there were any challenges because, truthfully, I had no idea what I was making! I just knew that I enjoyed experimenting and I continuously worked with waste paper and a set of bio-materials, until I began to develop an unusual, flexible end product with an interesting texture.

It was at this point that I was genuinely challenged to deal with my chosen ingredients and the process–I had to question what was causing this unexpected texture to occur in the material so that I could make it more prominent. Through a long process of trial and error, I found a balance of the ingredients and their ratios, while refining my making process. This has resulted in the uniquely patterned surface of BioMarble.

MD: Beyond its current applications and physical format, how do you see BioMarble existing and being used in the future?

Hannah: After seeing BioMarble for the first time, many people have asked me "So what does it do?”, to which I explain how waste paper has been recycled through the making of BioMarble, and that I want to encourage people to think more sustainably about materials.

However, I must admit that I am eager to start testing the functionality of BioMarble – I am now asking myself "So what does it do?" Or rather, "what could it do?". Could it be combined with other materials for optimal interior design and architectural uses? I feel that I could spend the rest of my life testing the material's possibilities!

BioMarble color and material testing, Hannah Elisabeth Jones

With our current throwaway culture as a society in mind, product design would be a fascinating field for me to explore; after all, designers have a huge responsibility and influence in this sphere when it comes to helping the environment. Sustainability cannot be a trend, it needs to be a permanent part of our culture.

MD: Having worked at the scale of site-specific and larger art installations, what is the next frontier for BioMarble?

Hannah: I would like to explore BioMarble as a practical material. For example, I would like to test whether it can be made waterproof and into a hard surface. However, there are specific issues with how I can achieve this sustainably. If I set BioMarble in resin or a form of plastic, it is no longer biodegradable, and you would not be able to experience its flexibility or unusual texture. But, it would be water resistant, and therefore it could become a more useful material for making products like table tops and tiling, etc. Additionally, if BioMarble could be set into recycled plastic or bio-resin, this would help tackle the problem of increasing plastic waste as well, while simultaneously consuming waste paper (through the making of the original BioMarble).

Hannah Elisabeth Jones - Commission for Vertical Gallery, Manchester School of Art, 2017

Hannah Elisabeth Jones - Commission for Bruntwood Offices, Manchester, 2017

MD: Your work has incorporated waste paper from your former university Manchester School of Art in the past. Do you see this process expanding into drawing waste paper from entire local communities or industries?

Hannah: Most definitely! I think my next source of paper would be from local schools, where I would be sure to make it known to both pupils and staff how their waste is being transformed and repurposed for artworks, functional products, and installation designs. Even though I would love to collect waste paper from as many sources as possible, the underlying concept of BioMarble is to encourage people to put their own waste to better use. And that more importantly, we need to reduce the amount of waste we are creating in the first place.

MD: Thanks so much Hannah, for these insights!

We're looking forward to seeing BioMarble evolve as a material, and your work being seen at even more forums. Readers, to learn more about Hannah's work, click here.